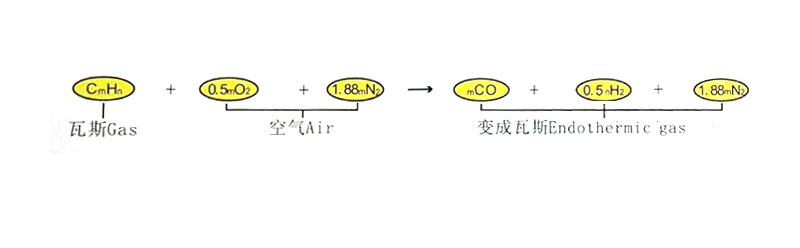

The endothermic RX gas conversion furnace is a device that mixes natural gas and a corresponding amount of air, and reacts with incomplete combustion under the action of high temperature and catalyst to generate a special atmosphere---commonly known as RX gas. RX gas is mainly sent into various atmosphere protection heat treatment equipment as a protective atmosphere; it can also be used as a carrier atmosphere in chemical heat treatment equipment, etc.

Scope of application:

●Non-decarburization annealing and spheroidizing heat treatment of medium and high carbon steel and alloy steel

●Carburizing and carburizing ammonium heat treatment of low and medium carbon steel

●Heat treatment for decarburization prevention

●Powder metallurgy

General reactivity: reducing, carburizing C precipitation tendency is large

Dew point:-5~+5℃

Way to heat up:

The raw material is propane, butane, natural gas and other hydrocarbon gas, which is mixed with air at a certain ratio.

Thermally decomposed in the catalyst heated at high temperature to generate CO, H2, N2, dew point -5~+5°C

Product Details

The composition of gas:

| CO% | CO2% | H2% | N2% |

| 21~24 | 0.4 | 40~42 | remain |

| Gas | M | N | Gas to air ratio | Recombination ratio |

| Methane | 1 | 4 | 1:2.38 | 1.44 |

| Propane | 3 | 8 | 1:7.14 | 1.55 |

| Butane | 4 | 10 | 1:9.52 | 1.57 |

Specification:

| Model | Gas generation(m³/H) | Raw material gas consumption propane(kg/h) | Cooling water consumption | Electricity(kw) | Equipment weight(kg) |

| ZMRX-40 | 7-25 | 3.9 | 1600 | 30~45 | 1800 |

| ZMRX-60 | 16-50 | 7.8 | 3200 | 35~60 | 2000 |

| ZMRX-80 | 24-75 | 11.7 | 4800 | 45~90 | 2500 |

| ZMRX-100 | 32-100 | 15.7 | 6400 | 60~90 | 3000 |

Hot Products